Early in 2012, we have begun manufacturing explosion resistant thermocouples and resistance thermometers for business and industry sectors utilizing flammable substances in either gaseous form, as mists or dust particles. These are available in a wide variety of make and design.

Since early 2012, we have been producing various explosion-protected resistance thermometers and thermocouples

certified to the ATEX (ATmospheres EXplosibles) directive

2014/34/EU for temperature measurements in liquid and gaseous

as well as dusty media. Previously only certified for intrinsically safe circuits of category Ex i, our assortment now expands to temperature sensors certified for Ex d (with pressure-resistant encapsulation) as well as Ex nA and Ex tc (without type testing certificate).

Application Areas for Our Intrinsically Safe Temperature Sensors

Our explosion-protected temperature sensors are designed as resistance thermometers or thermocouples and used in the classical industries of chemistry, petrochemistry, mechanical and systems engineering, food industry, crude oil and gas mining. They convert the temperature at the measured site into an electrical value (voltage, resistance) and serve to measure, register and control temperatures in the range of -196 °C to approx. +1800 °C in connection with the corresponding downstream units.

All GÜNTHER ex-sensors are built so that they cannot serve as an ignition source – even if any errors occur.

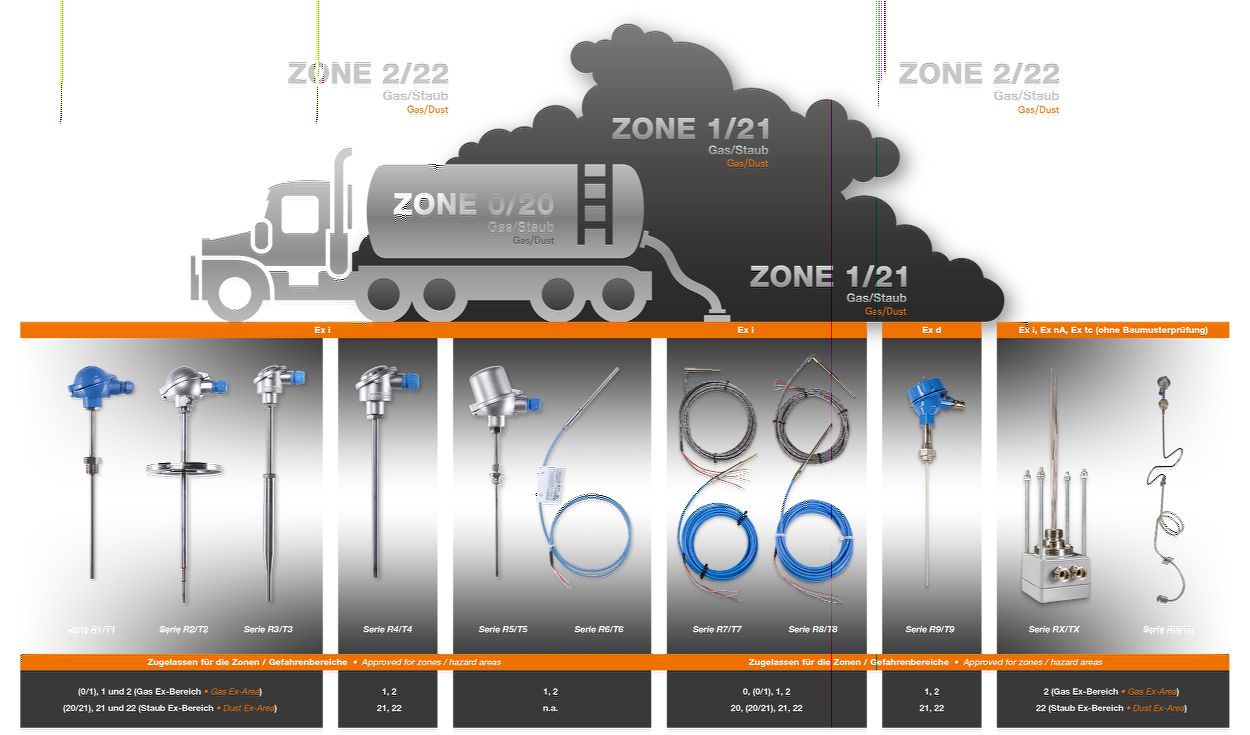

Product series and ignition protection types

The temperature sensors of the ignition protection type Ex i (product series R1/T1 to R8/T8) are certified for connection to

intrinsically safe circuits of category “ia”. The sensors of series R1/T1 to R4/T4 comprise a protective fitting with various process connections, a connection head and an exchangeable measuring insert. The temperature sensors of series R5/T5 and R6/T6 comprise measuring inserts with connection head or connection box and various process connections. They are designed either with simple protective tubes or as mineral-insulated lines with cable connections. Product series R7/T7 includes ex-sensors of a continuous or offset protective tube. Sensors of the product group R8/T8 contain mineral-insulated temperature sensors with connected supply line. Recently, GÜNTHER has been offering temperature sensors of ignition protection type Ex d with pressure-resistant encapsulation in different builds (series R9/T9), as well as sensors of ignition protection type Ex nA / Ex tc.

Setup and equipment

The resistance thermometers have common resistors of platinum or nickel installed. These temperature sensors are produced according to DIN EN 60751 and available in all common tolerance classes in two-, three- or four-conductor technology. Designs with two measuring circuits are possible as well. The thermocouples are equipped with T, J, K, E, S, R, B and N elements according to DIN EN 60584 in tolerance class 1 as simple or double measuring circuit, which makes them suitable for use in potentially explosive areas with gas or dust. Depending on application and measuring task, the temperature sensors can be equipped with various process connections, lines and connection heads. For this, our sensors are optimally designed for customer-specific requirements and also available ex stock on short notice.

For more information on each intrinsically safe product series please read our PDF offered in the top of right column.

Choose your language

Leave your number and we’ll call you back

Your direct contact to our team

GÜNTHER GmbH

Temperaturmesstechnik

Bauhofstraße 12

D-90571 Schwaig

info@guenther.eu

Tel. +49 (0)911 / 50 69 95-0

Fax +49 (0)911 / 50 69 95-55