Technical Information

1. Construction

Today in the field of industrial temperature measurement resistance thermometers with platinum sensor resistances are predominantly used.

Advantages over conventional sensors exist particularly

- the small dimensions

- the closed structure

- the short response time

- the high temperature durability

- in the resistance against chemical and mechanical effects and

- the high service life and stability.

Because of the closed structure of the resistance thermometers it is possible to use them even without further protection fitting.

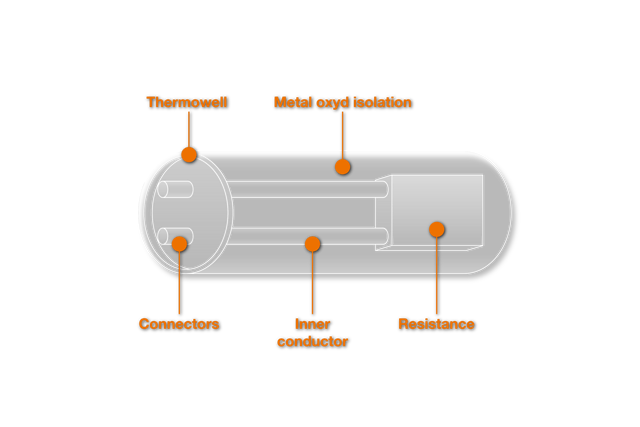

A resistance thermometer always consists of the following components:

- A temperature sensitive laboratory resistance, usually Pt100

(other resistance values are possible) - the inner conductors (input and output)

- the insulation material (metal oxide powder) and

- the thermowell.

Fundamental construction unit is the temperature-dependent sensor resistance attached respectively at the sensor point. This resistance is flowed through by an auxiliary current, which can lie between 0,1 and 10 mA , may not exceed 1mA however, in order to avoid a heating up of the sensor by the signal current, the respectively adjoining electrical resistance is measured. Because of this accurate conclusions on the ambient temperature of the resistance can be made on the basis of the DIN EN 60751, which standardizes this resistances from 200°C to + 850 °C, up to three sensor resistances can be included in a sensor.

Sensor resistances which at 0°C show exactly 100 ohms are described as Pt100, those which have 500 ohms resistance at 0°C will be shown as Pt500 and resistances with 1000 ohms at 0°C as Pt1000.

Choose your language

Leave your number and we’ll call you back

Your direct contact to our team

GÜNTHER GmbH

Temperaturmesstechnik

Bauhofstraße 12

D-90571 Schwaig

info@guenther.eu

Tel. +49 (0)911 / 50 69 95-0

Fax +49 (0)911 / 50 69 95-55